QCS Rohrpost: The automation specialist for Quality Control Systems

How do you go from being an internationally recognized project manager at Pfaff aqs and FLSmidth to a pioneer in automation for quality control systems? What past do Peter Niemann, CTO at Fink & Partner, and Heinz Sepke, Managing Director of QCS Rohrpost GmbH, share? Learn more about the strategic partnership of QCS Rohrpost GmbH and Fink & Partner GmbH and how you can benefit.

Heinz Sepke, Managing Director of QCS Rohrpost GmbH, looks back on more than 40 years of experience as a project manager at Pfaff AQS, FLSmidth, and ITCS GmbH, for example. At FLSmidth, Heinz Sepke and Peter Niemann, CTO at Fink & Partner, met for the first time. Joint automation projects for China Steel, BAO Steel, Tata Steel, and JSW Steel,among others, created a respectful basis of trust over the years.

In 2014, the FLSmidth group decided to close the site in Wuppertal, Germany, and move to China. Unlike FLSmith, Heinz Sepke saw great potential in keeping close to customers in Germany and offering Quality Control Systems for any industrial application (STEEL, CEMENT, MINING, CHEMICAL, NON-FERROUS, and RECYCLING), just as the owner-operated company Pfaff AQS once did:

- Steel (steel, iron, and slag)

- Cement (cement, raw meal, hot meal, clinker, kiln feed)

- Mining (iron ore, gold, phosphate, and other precious metals…)

- Chemical (colorant, powder, and wet chemical)

- Non-Ferrous (copper, aluminum, zinc, nickel, rare earth, lead, tin, titanium, bronze, other alloys…)

- Recycling (electronic scrap, substitute fuels)

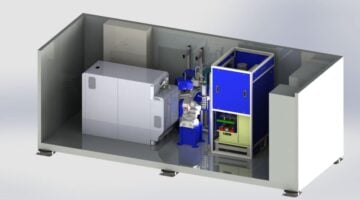

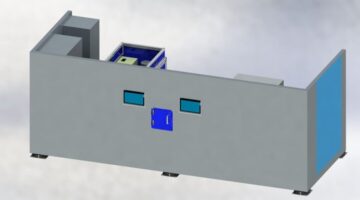

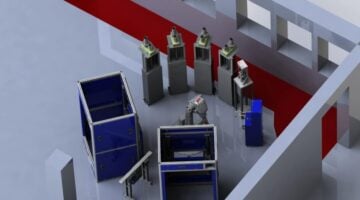

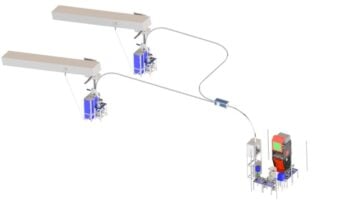

The foundation stone for QCS Rohrpost GmbH was laid, followed by the foundation in 2015. QCS redeveloped all equipment and systems, such as those for sampling, sample transport, sample preparation, and sample analysis, and brought innovations. Initially, the owner-managed company focused on the DACH region, but now companies from Croatia, Sweden, Spain, and Iceland are also part of their customer base. Many well-known global companies rely on the expertise of QCS Rohrpost GmbH.

Today, seven years after its foundation, the company consists of 15 employees who offer their customers a complete package, from the system’s design to the programming of PLC and robot control, as well as software solutions for material sample management to mechanical and electrotechnical manufacturing and assembly. Moreover, development has progressed so far that Heinz Sepke and Mario Sepke, who joined the company as Business Development Manager in 2022, would like to focus on strategic internationalization. In this context, they remembered the highly successful projects with Fink & Partner and contacted them to discuss a strategic partnership. Philip Mörke, CEO of Fink & Partner since 2018, was immediately enthusiastic about the idea of strategic collaboration, as it also offers value to Fink & Partner’s customers.

Unique selling propositions that convince

QCS Rohrpost GmbH offers its customers several unique selling points, which Fink & Partner also defines as such for itself. Certainly also one of the reasons why strategic cooperation makes sense.

- Individuality: Unlike other suppliers, QCS offers customized/individual Quality Control Systems for its customers. The systems are also developed so customer-specific extensions can quickly and cost-effectively incorporate into the standard automation.

- Dynamism: When challenges arise, QCS is dynamic in finding solutions due to its lean and fast ways of achieving efficient implementation at the customer’s site.

- Partnership connections: Trustful cooperations make the impossible possible. QCS Rohrpost GmbH is thus able to develop the appropriate sampling, sample transport, sample preparation, and sample analysis system for almost any primary, raw, or processed material. The partnership with the experts at Fink & Partner, for example, enables the company to make LIMS systems compatible with any analytical instrument manufacturer in the process.

- Sustainability: QCS designs its systems and products pragmatically and with foresight so that they can be maintained without significant effort or, in the event of malfunctions, intervened without much delay. User-friendliness is particularly important to QCS in this regard.

Examples show: Products from QCS Rohrpost make processes significantly faster

What do the products from QCS Rohrpost actually do in practice? According to Heinz Sepke, most customers are primarily concerned with the following question: How can the sample be examined for its materials as quickly as possible and with a high degree of reliability? The following application examples show: With QCS Rohrpost products, the process can often be carried out twice as fast.

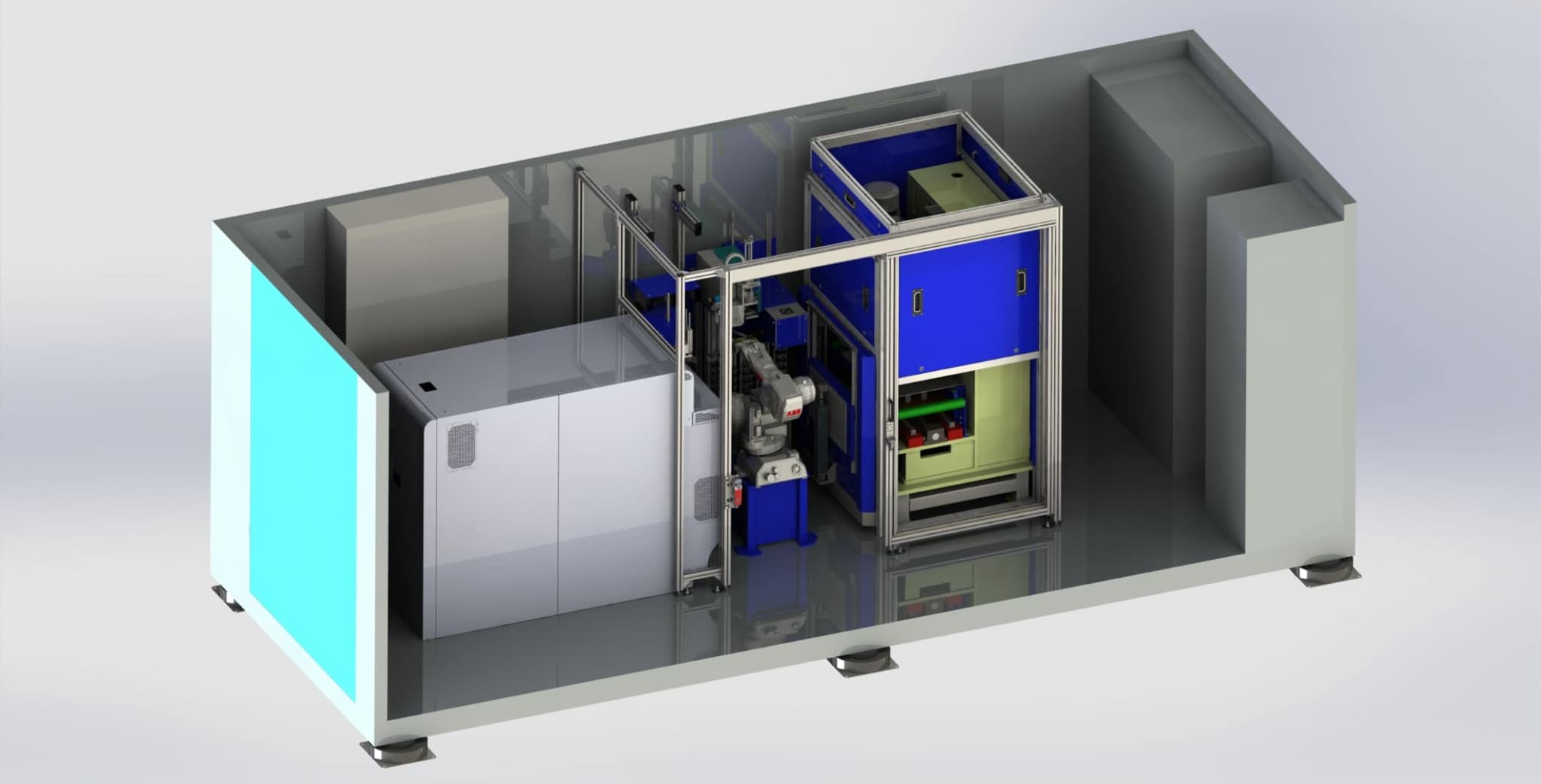

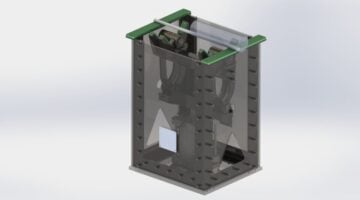

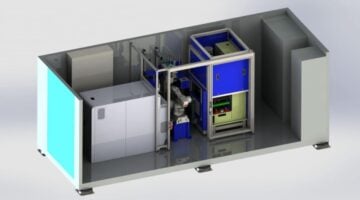

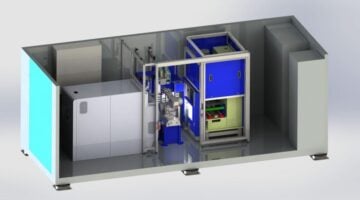

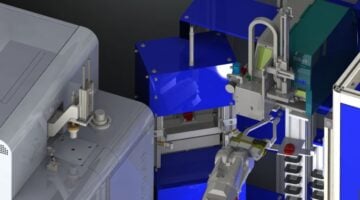

- Example: QCS Laboratory Container CL100

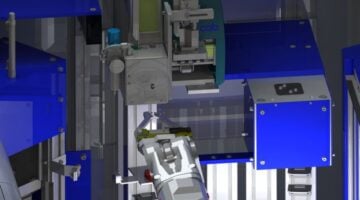

The entire cycle from sampling to sample analysis takes 2 minutes with the QCS Laboratory Container. In an aluminum and steel plant, this means that, on average, up to 500 samples per day can pass through quality control. Very conservatively, the conventional cycle takes at least 4 minutes. Now it depends on how many samples have to be taken before the steel crucible, which is heated to over 1,000 °C and sometimes contains 30-40T of liquid steel, can be poured off. In any case, it can be said that more steel is produced while maintaining the same quality. - Example: QCS Automatic Positive Material Identification (PMI) AW100

With the QCS automatic positive material identification, quality control, incl. sample preparation of a finished steel pipe with a diameter of up to 100mm, can be checked within 22 seconds. In addition, the process is fully automated during production, enabling a 24/7 turnaround time. Previously, quality control had to be done manually by an employee using a handheld spectrometer. Very conservatively, this manual cycle took at least 1 minute, assuming that the employee’s performance and concentration remained consistently high for hours.

Common goal: to make laboratory processes significantly more efficient

The LIMS software [FP]-LIMS also makes laboratory processes significantly more efficient. For example, the solder manufacturer STANNOL confirmed that they could reduce the laboratory’s documentation effort by 80% by using the [FP]-LIMS solution. The strategic partnership of QCS Rohrpost GmbH and Fink & Partner GmbH is, therefore, a real asset for all companies from the application areas of steel, cement, mining, chemicals, non-ferrous metals, and recycling that want to make their laboratory processes more efficient.

Your direct contact to the automation specialist:

Mario Sepke

Business Development Manager at QCS Rohrpost GmbH

E-Mail: [email protected]

Tel.: +49 (0)2191/8909347

![Flexible and customizable LIMS software at an affordable price - [FP]-LIMS Flexible and customizable LIMS software at an affordable price - [FP]-LIMS](https://blog.fp-lims.com/wp-content/uploads/2025/01/Flexible-and-customizable-LIMS-software-at-an-affordable-price-FP-LIMS.png)

![Transaction Data in LIMS - Flexibility and application diversity with [FP]-LIMS Transaction Data in LIMS - Flexibility and application diversity with [FP]-LIMS](https://blog.fp-lims.com/wp-content/uploads/2025/01/Transaction-Data-in-LIMS-Flexibility-and-application-diversity-with-FP-LIMS-1024x1024-394x330.png)