WHAT IS A TENSILE TEST?

The tensile test is a destructive test procedure that is used in materials testing. The decisive factor for the measurement is the elongation of the specimen, which is defined by the change in origin and length.

Tensile test procedure: How does the tensile test work?

As the name implies, the tensile test loads a workpiece with a defined cross-section. This load changes the shape of the body. Elastic deformation occurs first. This means that the body will return to its original shape when it relaxes.

If the body reaches its yield point, the point where the elastic elongation stops, it is irreversibly extended in shape. The body now enters the phase of plastic deformation. If the load continues, the body reaches the point of tensile strength. At this point, the test piece absorbs the maximum bearable force. Then the constriction of the body begins up to the break.

Application: These findings can be derived from the data

In comparison with other materials, the body can now be divided into two categories: Ductile and brittle. The body is ductile if it can withstand high loads, brittle if the body shows signs of fatigue even under fewer loads.

The deformation process can be represented in a stress/strain diagram. The points of yield strength, tensile strength and yield strength (0.2% plastic deformation) are clearly visible.

The data obtained is central to the work of structural engineers and engineers. The maximum permissible load of components can be determined by the load limits of the material, taking safety limits into account. This is used in numerous areas, including bridge construction and the transmission of a motor vehicle.

Which devices are used for determination in industry?

The well-known ZwickRoell devices are used in tensile testing. Particular attention must be paid to the standard-compliant execution of the test. Metals are often subjected to tensile testing. The material properties can now be obtained by analyzing the data up to the point of material failure. In order to ensure a comparable basis for all measurements, the devices must repeatedly achieve reliably standardized test procedures.

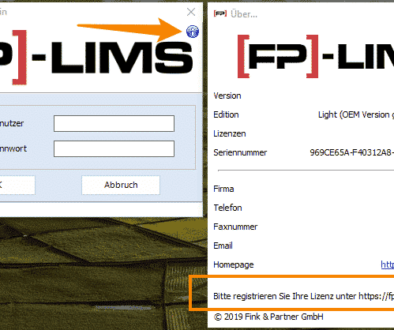

In order for the results to provide the desired findings, the data must be managed. Laboratories all over the world use so-called LIM systems to compare different measurements. This stands for Laboratory Information and Management System. In this way, the results of the tensile test can be transferred directly from the measuring device to the software via automated sequences. The results are stored centrally and analyzed further. The analysis of these raw data now provides information about the desired findings.

Fink & Partner – Your reliable LIMS for individual requirements

Fink & Partner is a provider of a powerful LIMS system with a multitude of interfaces to literally all measuring instruments. The [FP]-LIMS offers customers all over the world an efficient system to increase productivity in the laboratory. The system thus guarantees successful quality management and supports development and research.

Are you also interested in the LIMS from Fink & Partner? One of our experts with many years of experience will be happy to offer you professional advice. We look forward to hearing from you!