WHAT IS A HARDNESS TEST?

A widely used method for measuring the mechanical resistance of surfaces is hardness testing. There are various methods for testing the hardness of a component or material.

An overview of the common hardness testing methods

The methods used to measure hardness differ with the body shape of the object being measured. For example, there is Brinell hardness, Rockwell hardness and Vickers hardness. The Brinell method and the Rockwell method both use a standardized ball as the entry body. The Vickers method is based on an equilateral diamond pyramid as a tool. The test piece is placed on the surface of the material to be tested and a standardized force is applied. The entry depth of the tool is then measured and the degree of hardness is determined on the basis of this depth.

Further methods of hardness testing are Martens, Knoop, Shore, Barcol, Buchholz and many others.

Why measure the hardness of materials?

The hardness of materials is an informative property. It provides information on the wear resistance of materials. Especially in the field of tool cutting equipment, hardness plays a decisive role as a material property.

Hardness test: Which devices are used to measure hardness?

Since hardness is a central material property, all kinds of devices are available on the market. Especially the ZwickRoell instruments have proven to be reliable in the procedure of hardness of metals, plastics, rubber and special materials. Of course, all applicable standards are taken into account.

Hardness testing is used for quality management. The quality of the products and materials is checked at incoming and outgoing goods. For the management of the acquired data it is a good idea to use software for the correct flow of information.

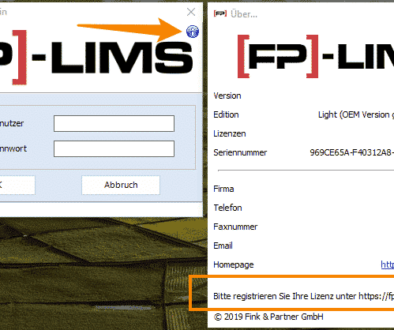

![[FP]-LIMS hardness test [FP]-LIMS hardness test](https://blog.fp-lims.com/wp-content/uploads/2024/01/FP-LIMS-hardness-test.jpg)

Fink & Partner – The LIMS in Quality Management

Fink & Partner’s LIMS is used especially in the area of quality management. Thus, the data aggregated by a measuring device can be automatically forwarded to the software. Evaluations of the data ensure that the quality standard is maintained. Since the LIMS from Fink & Partner works exclusively with raw data, it is possible to automate documentation. In addition, the course of the quality can always be checked and in case of non-compliance the origin can be quickly found.

Are you interested in using the [FP]-LIMS? Our experts will be happy to advise you on the further planning of your project. We look forward to hearing from you!