LIMS SOFTWARE FOR YOUR CHEMISTRY 4.0 IMPLEMENT CHEMISTRY 4.0 WITH LIMS INTO YOUR LABORATORY AND IMPROVE YOUR PROCESSES

Are you working in a chemical laboratory, and you are asking yourself how you can reach the standards of Chemistry 4.0? LIMS software belongs to the current upcoming standards.

Like the metal casting and foundry industry, chemistry is evolving towards automation and digital technology as well. The chemical application field is even bigger than the metallurgy one and centers on upcoming requirements that need to be explained.

According to finance experts, the global chemical industry employs more than 20 million people, has an annual sale of $5 trillion, and serves as the backbone of many other industries such as agriculture, automotive, construction, and pharmaceuticals. Therefore, the changes in the chemical industry will have a significant effect on various other industries.

The chemical industry contributes to almost every manufactured product since it is responsible for its chemical composition.

Based on the assumption that Industry 4.0 involves the automation and digitalization of smart manufacturing processes, we can affirm that the chemical industry will have to adopt many changes. Industry 4.0 is also known as the Fourth Industrial Revolution, and according to the manufacturing fields, involves many innovations such as Industrial Internet of Things (IIoT), Machine-to-Machine (M2M) communication, artificial intelligence (AI), and cloud and cognitive computing.

Another key concept of Industry 4.0 is Quality 4.0, which is supposed to improve productivity, optimize processes, reduce costs, and risks. These strategic objectives have a predictive asset management function, as well as process control and production simulation. Pointing on reducing risks is also an upgrade to improve safety and quality.

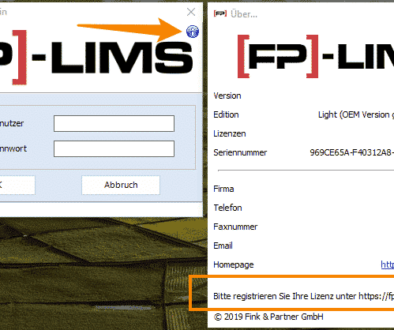

There is not a single Industry 4.0 product or solution, though. Manufacturers can choose between different options of new technologies that can help them compete with other companies. One of these solutions is LIMS software. As an example of a LIMS solution, we will take into account [FP]-LIMS, developed by the German company Fink & Partner GmbH.

Definition LIMS means Laboratory Information Management System and is one of the most used software solutions in laboratories nowadays. LIMS is known for its flexibility and reliability: in fact, this laboratory software takes care of sample management and collection, analysis, and storage as well as laboratory workflows management and statistical evaluation.

The ability to enhance recruitment is crucial for the chemical industry. More than other manufacturers, the ones working in chemicals face pressing needs to obtain real-time data to maximize efficiency. Thus, this optimizes the production processes and the customer experience based on a service-oriented business model.

Productivity in the chemical industry centers on predictive asset management, process control, and production simulations. Advanced IIoT-technologies, like [FP]-LIMS, can support companies optimize their maintenance spends and efficiency through predictive or digital maintenance. Laboratory data can be, therefore, continuously collected from measurement instruments.

In this case, the laboratory equipment must be supported by LIMS since it can collect and manage samples and connect the measurement instruments with each other – even if they were produced by different manufacturers – and store the collected data into [FP]-LIMS. [FP]-LIMS also supports communication with upper-level systems, such as ERP and SAP S/4HANA®. The software sends then the disposal order to ERP according to pre-defined rules. Finally, laboratory technicians and clients can access the stored data any time they need it.

To sum up, [FP]-LIMS is a cost-effective and reliable solution to improve your chemical laboratory and to make a step towards Chemistry 4.0. In fact, it can optimize all the processes for manufacturing from the next-generation business.